Forest Contracts Ltd

March 2025 - Present

Forest Contracts joinery company specialising in hotel and bespoke furniture. I was brought on as part of a new design team to help unify the company as the old department was located in Yorkshire while the factory and main office down in Essex.

Our team was tasked with not only taking up the mantle of designing our furniture but at the same time updating and streamlining dated systems. I wanted a focus on working closely with the factory and purchasing departments, trying to make sure what we were producing gave them the information they needed and needed little to no changes on their end. A disconnect between the old Design Department and the Factory had lead to a large number of issues and a slower than desired manufacturing time.

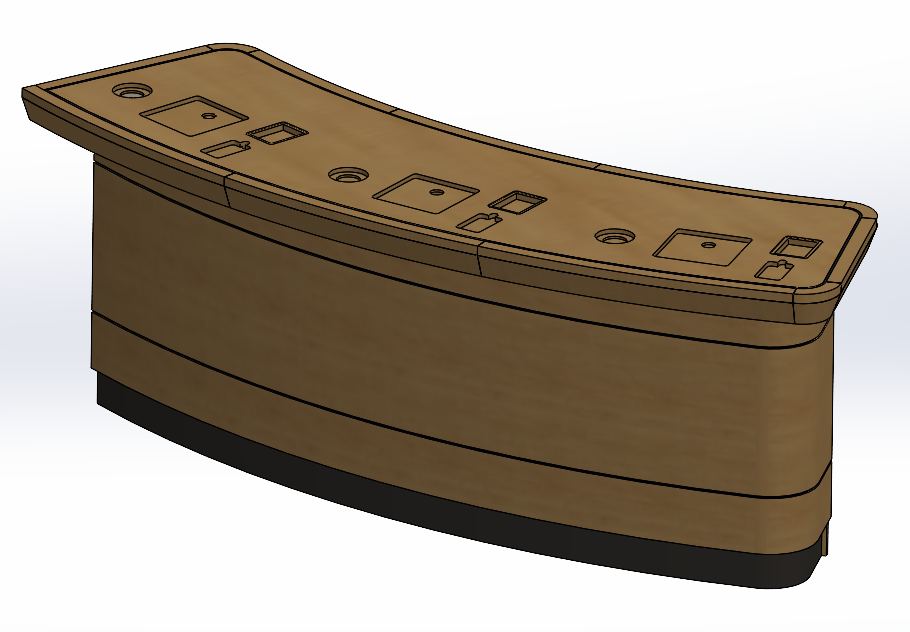

My day to day responsibilites focused on our main Quote and Order Jobs. These would be sent through from the estimating team as could vary from one or two items through to full roll-outs of hotels that could be several hundreds of rooms.

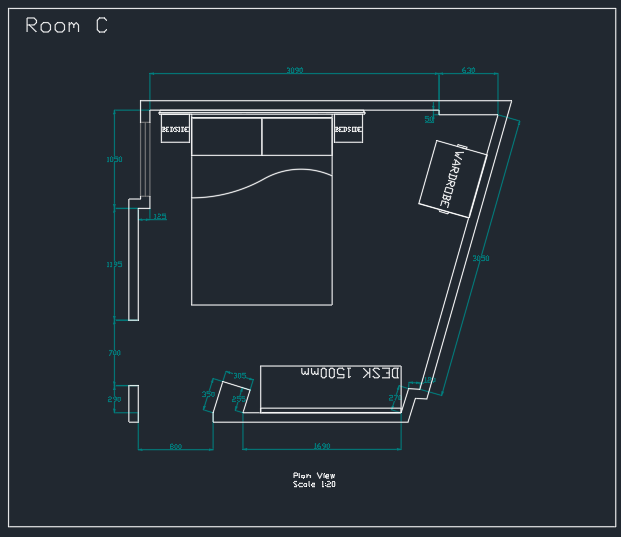

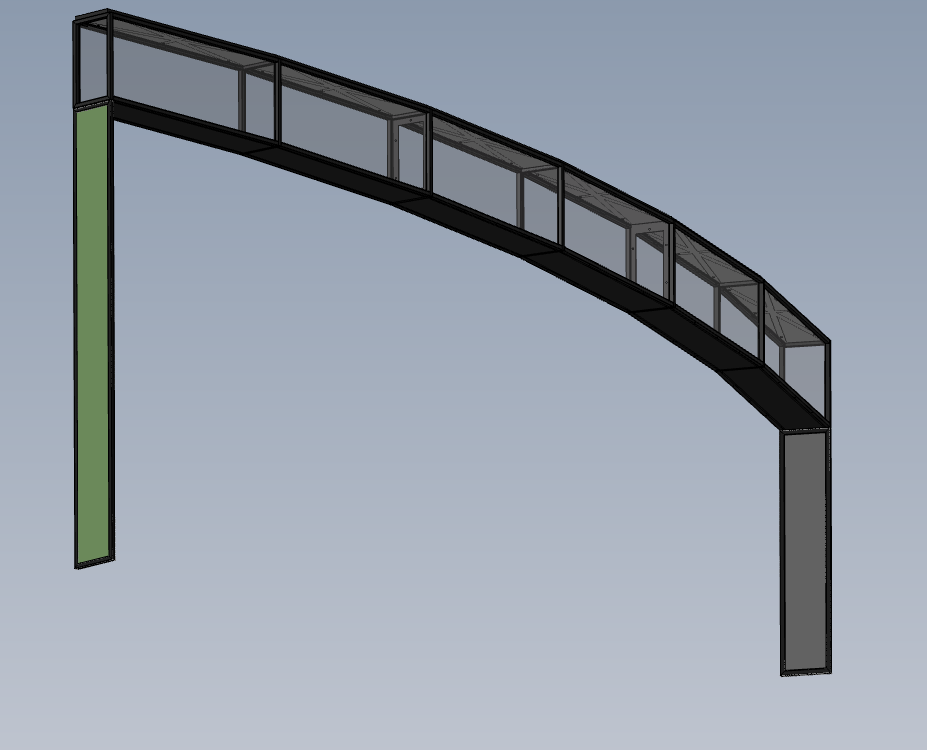

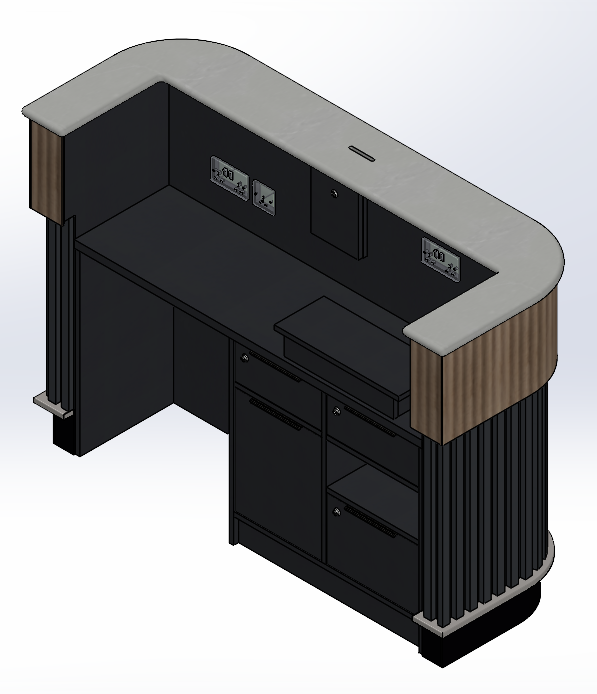

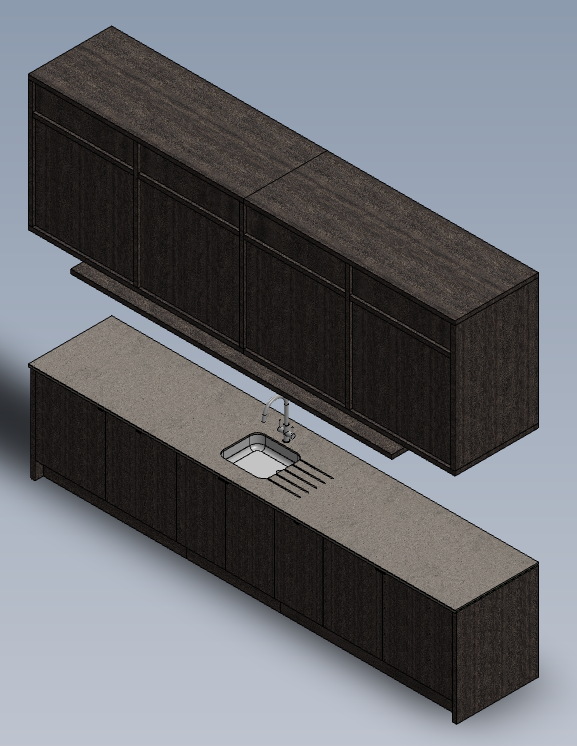

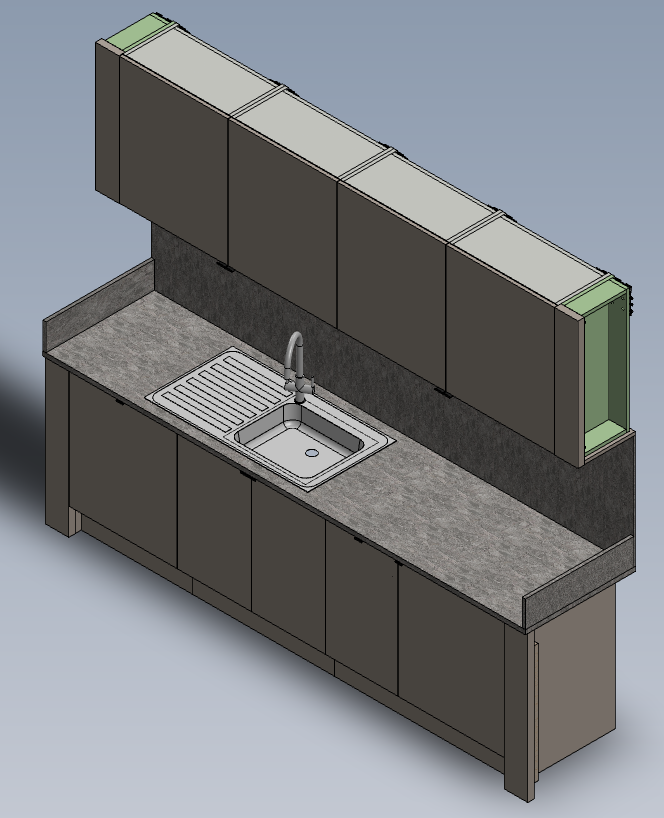

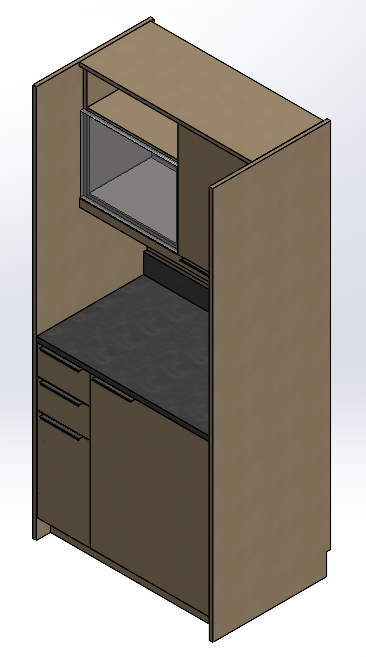

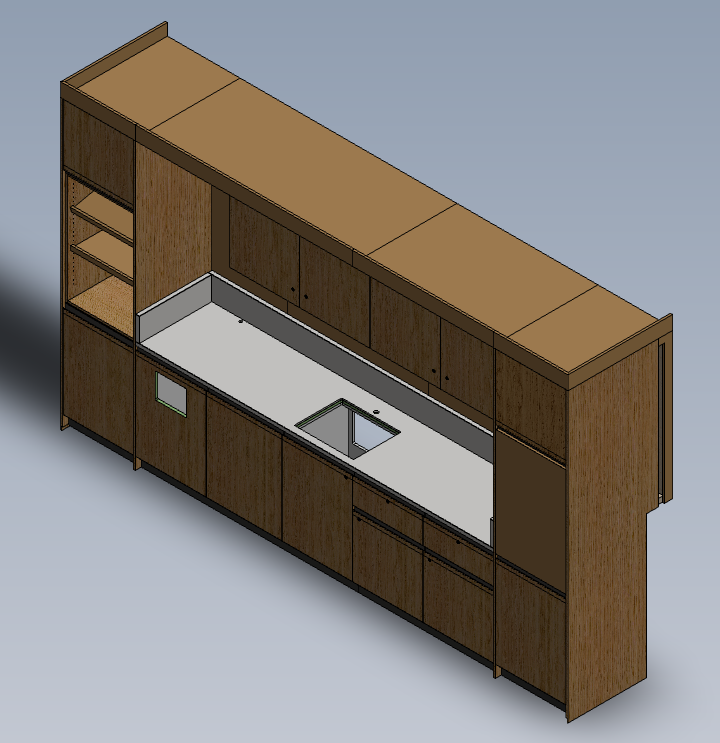

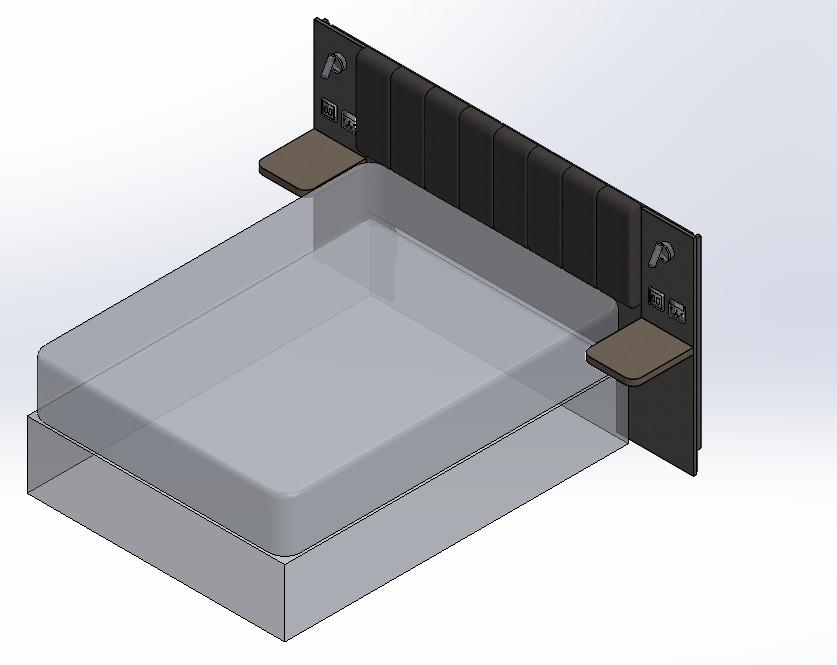

A quote-level job was usually requested to help us win the full order. Most of these consisted of drawing up survey notes to give the estimating team an accurate layout of rooms, producing top-down room layouts, or making quick 2D or rough 3D models of furniture to help visually show the client what they would be getting.

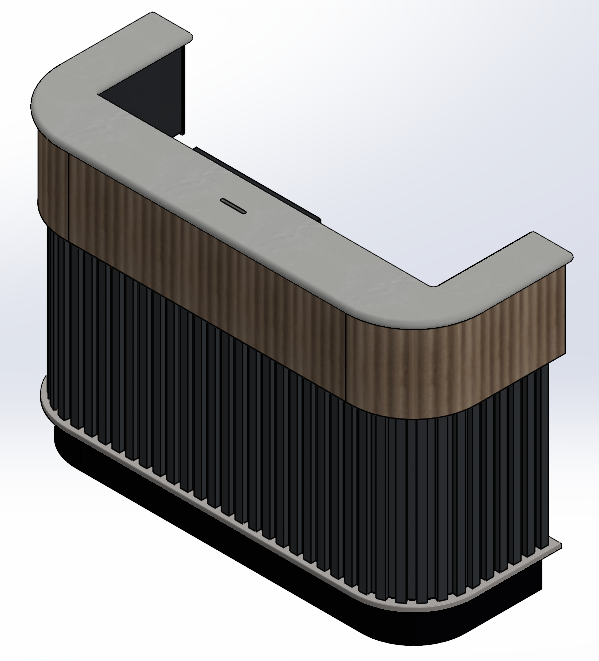

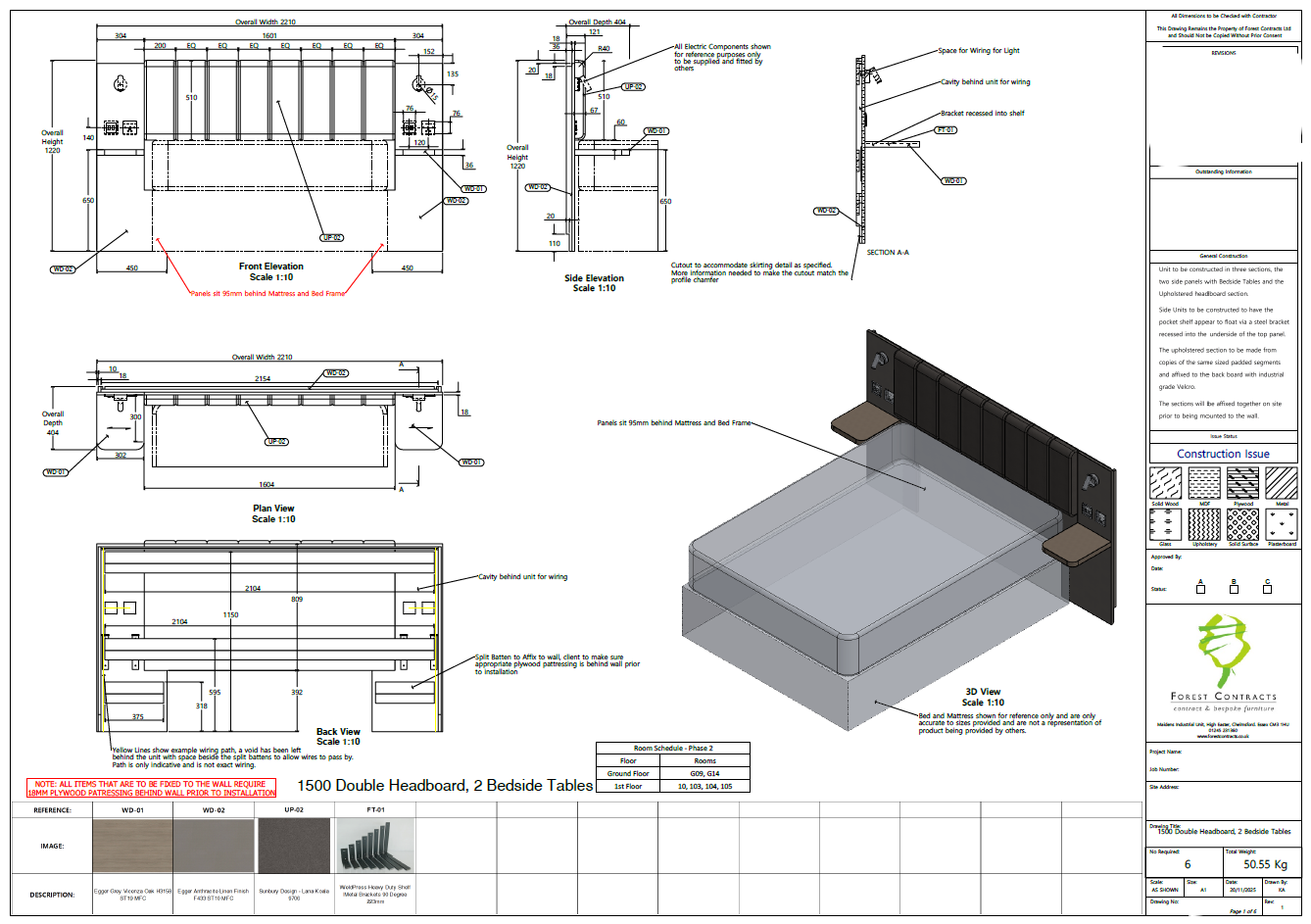

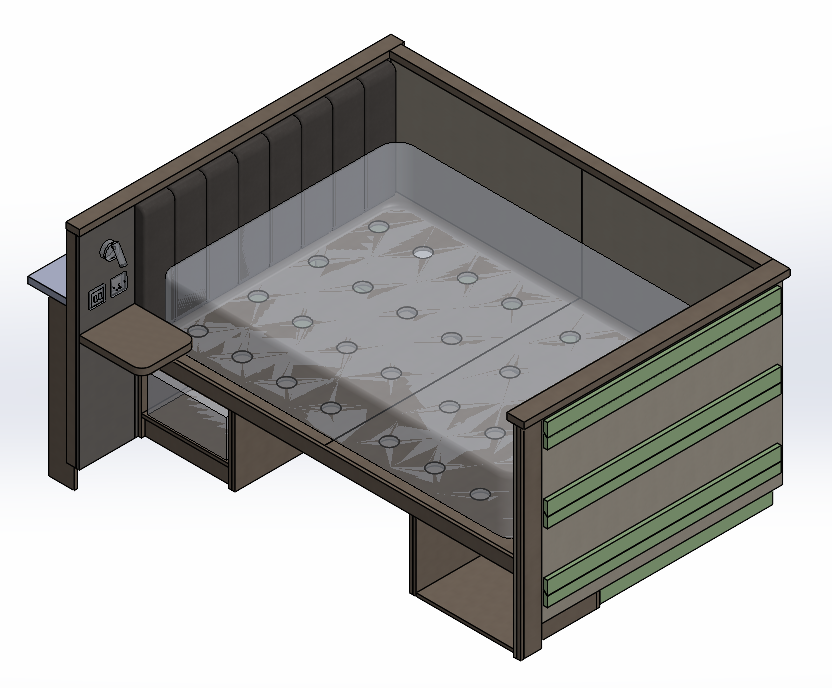

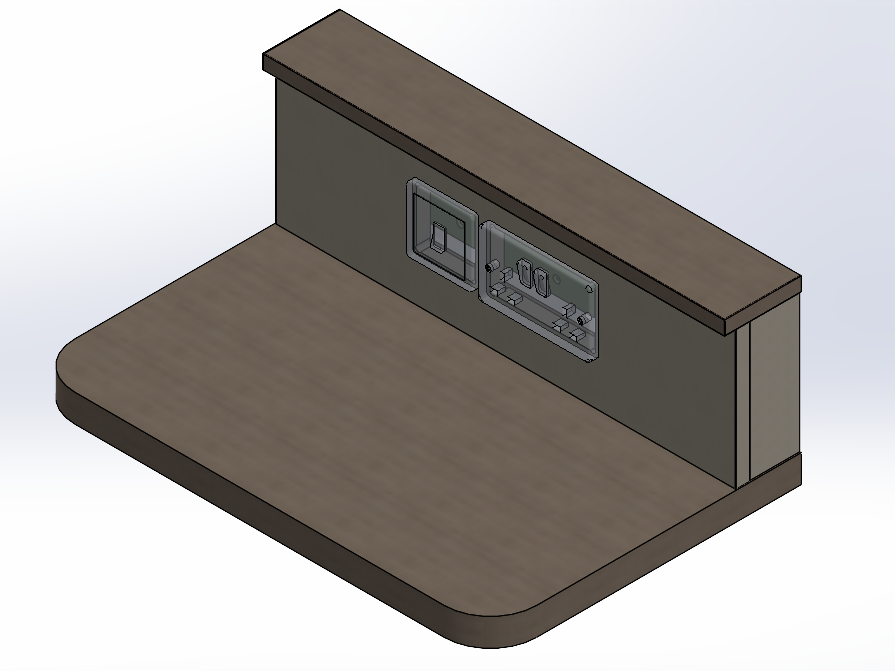

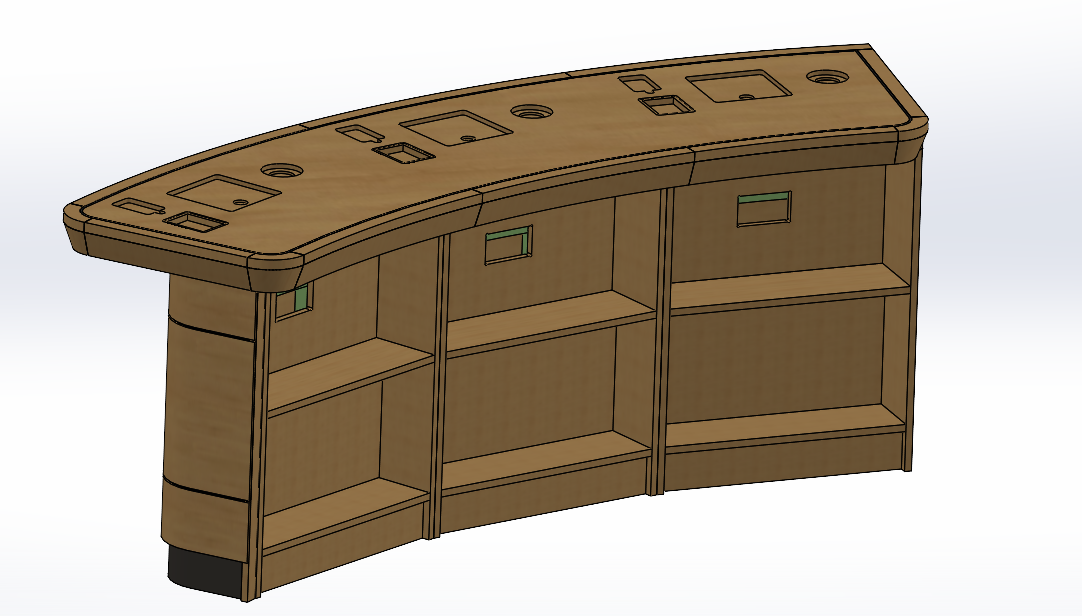

Order level jobs were where the majority of my time would be spent. At this point, we had a full approve quote and a deposit paid, the estimating team would send over to us the full drawing package to start modelling up furniture in Solidworks. These packs varied in detail depending on the job, usually had a rough overall idea of what the client wanted but no specifics, and usually needed interpreting to actually be manufacturable. Though sometimes I would have full creative freedom with only a few guidelines, such as “open faced wardrobe with front to back hanging.” In these instances, I would request if the client had any photos of inspiration or desired aesthetic. However happy to work without. On rare occasions, we would have near manufacturable drawings; they just needed to be transitioned into our system to work with the manufacturing team and hardware added.

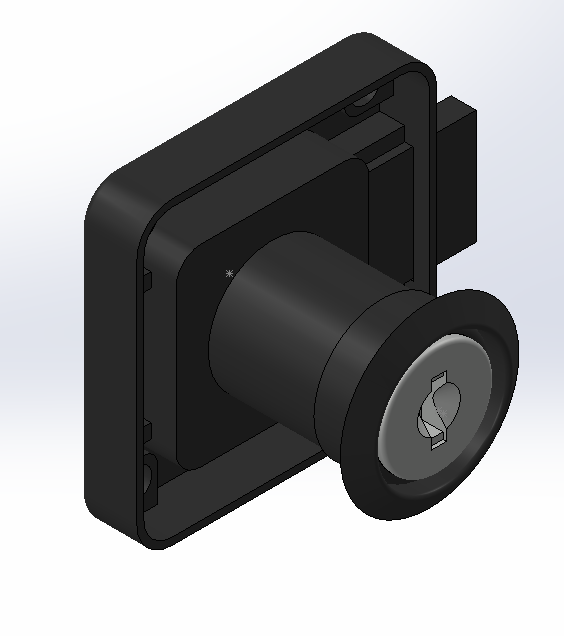

The majority of our work was modelled in SolidWorks, though layouts would be either SolidWorks or AutoCAD (only one licence of AutoCAD, so adapting to meet time constraints). Part of the new design team's input was to make all our models parametric, so that client changes could be easily adopted, so we had a focus of sketch driven models and large use of equations. Once the model was complete, we would produce a drawing and submit it over to the client as first issue. In a perfect world, that would then be approve,d and we could transition the item to constrcution issue. But with most industries, the client would usually request changes or a site survey would flag a need for a design change.

Once the model had been client-approved, we would adapt the drawing to be used on the workshop floor, such as adding exploded views or adding manufacturing notes. We would also produce a BOM to be input into the company's Shopping List, essentially a cutting list with other sections for hardware, room configurations, and other details.

This altogether would be submitted to the factory to start programming and manufacturing.

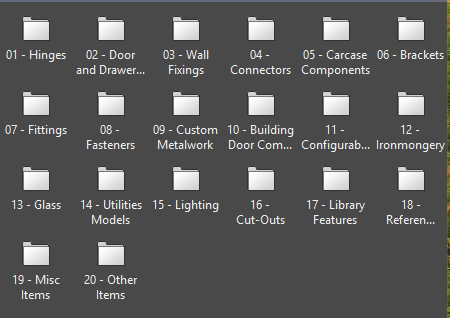

On the subject of Hardware, one of my biggest accomplishments at the company was to implement a library of hardware with custom properties attached, with all information needed to order. In my first weeks, I discussed how hardware information was given to the purchasing department and assembly teams, their response was a part number at most usualy and rarely consistently using the same items from job to job. Even some items just have generic descriptions, and the purchasing department has to find something and hope it works with the item.

I decided to take some time, usually 30mins a day, to build up a library focusing on the items we preferred and worked best across a large number of items. I spent time talking with the factory, installation team, and purchasing to find what we wanted to be our standard items. These were the basis of this new library, immediately saving purchasing time by having things such as supplier, part number, link, and part description within the file and thus on the shopping list. From then on I made sure any time I needed to use a new piece of hardware, it was added for future use, leading to a currently 300+ strong library.

Some of these models would be from suppleirs but sometimes no model was available or was not suitable for our use so I would say about 1/3 of the library was modelled by myself to make it suitable to our uses.

Throughout this page, you will find examples of my work, both models and installed images. I wish I had more images of the items in their final locations, but this was not something our installation teams always had time for. Below is an example from where I have images of an item I designed and installed.